- Home

-

Products

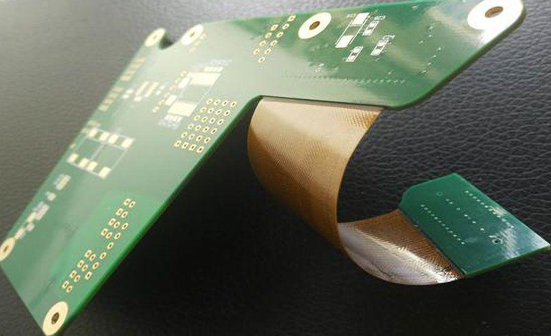

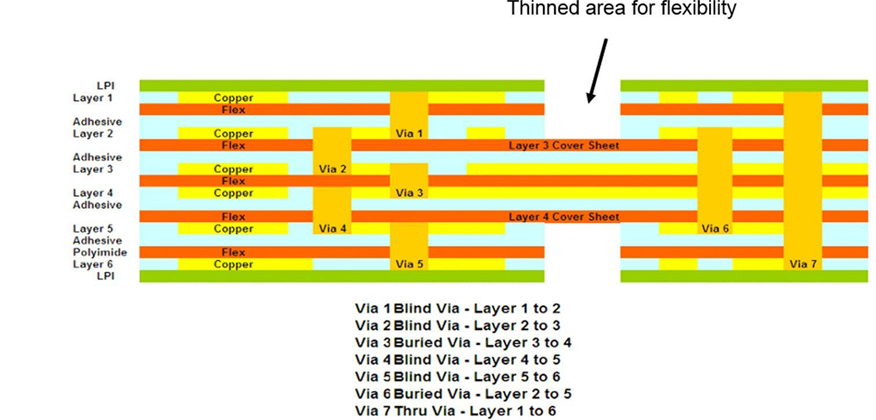

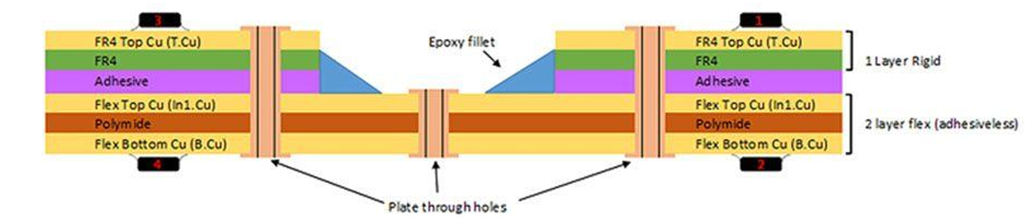

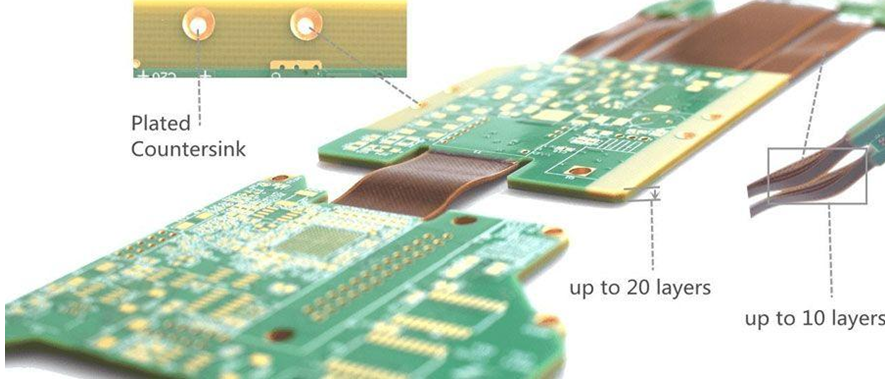

PCBA Board Assembly Industrial Control PCB Assembly Medical PCB Assembly Communication PCB Assembly Automotive PCB Assembly Drone PCB Board HDI PCB Board High Layer PCB High Frequency PCB High Speed PCB 5G Optical Module PCB Semiconductor PCB Thick Copper PCB Industrial Control PCB Consumer Electronics PCB Rigid Flexible PCB RF Antenna PCB

- About Us

-

VR factory visit

- News

-

Contact Us

-

Language

-

-

PCB/PCBA QUOTE