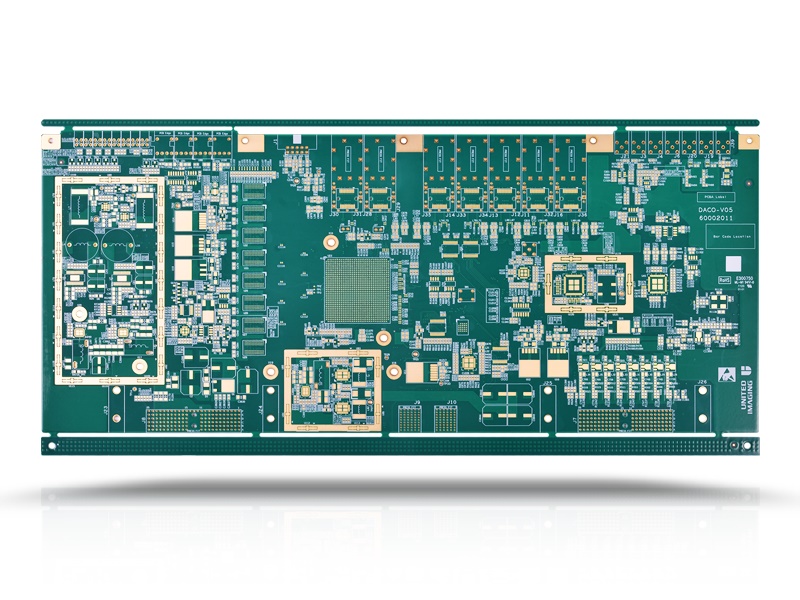

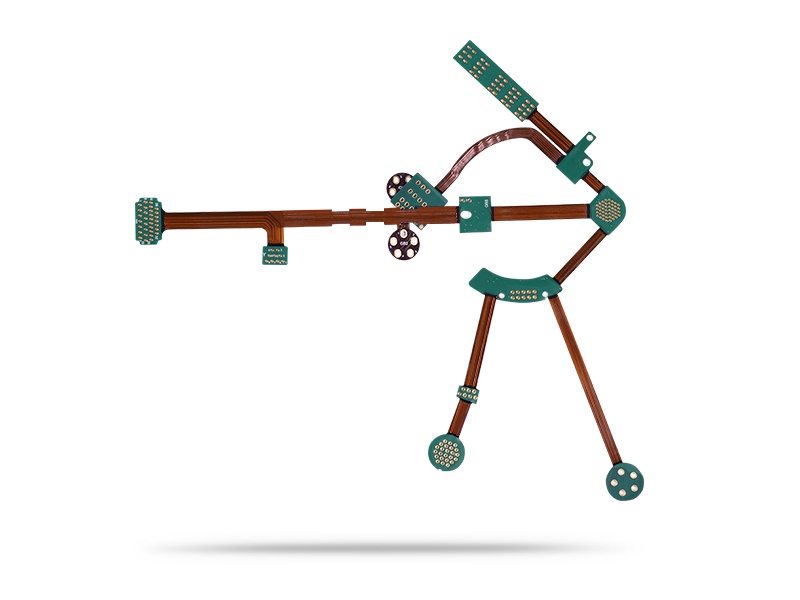

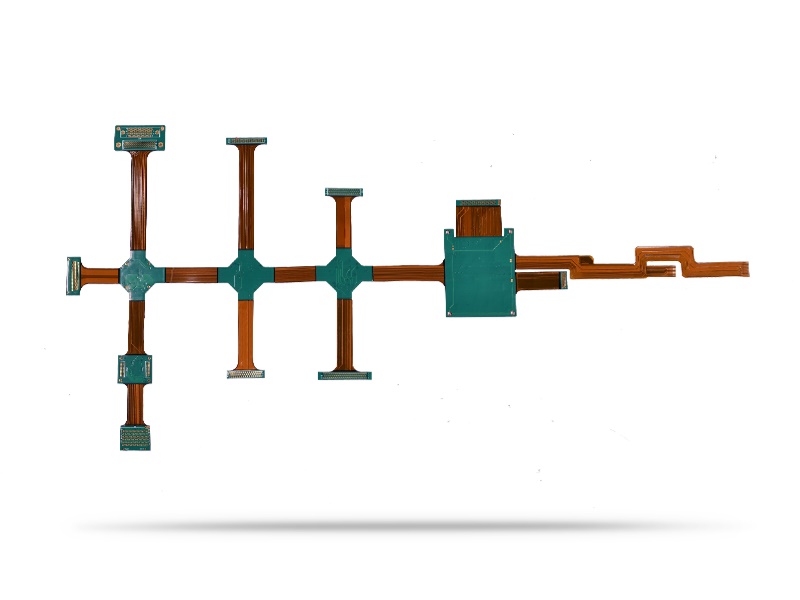

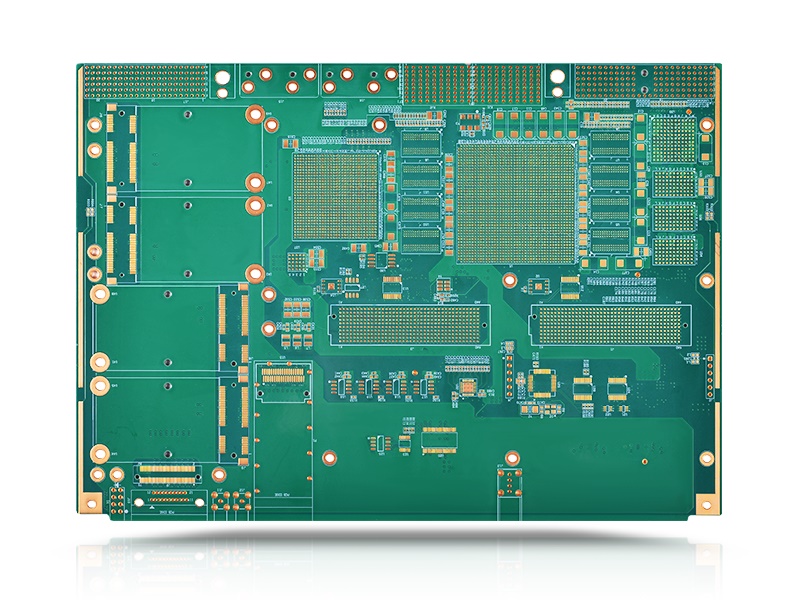

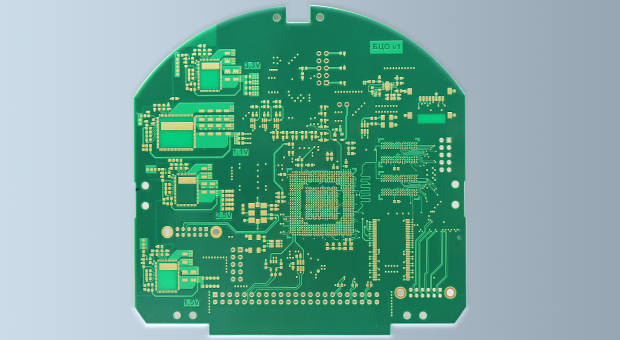

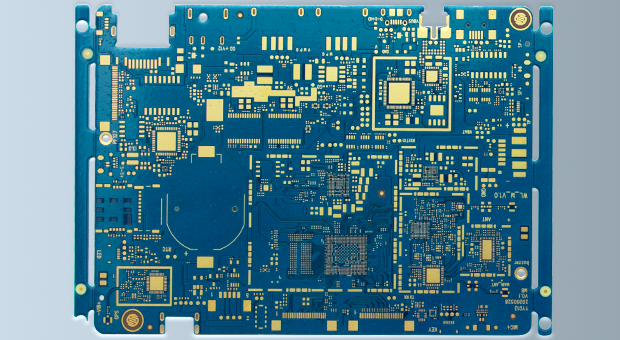

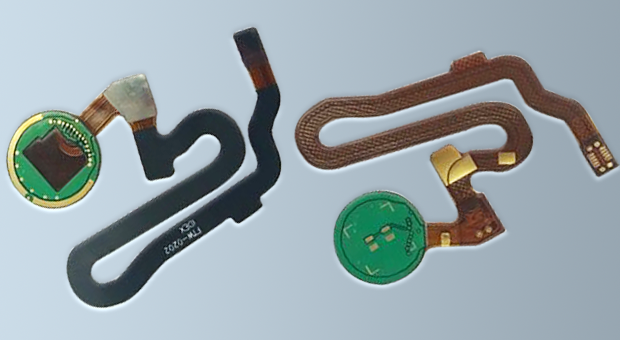

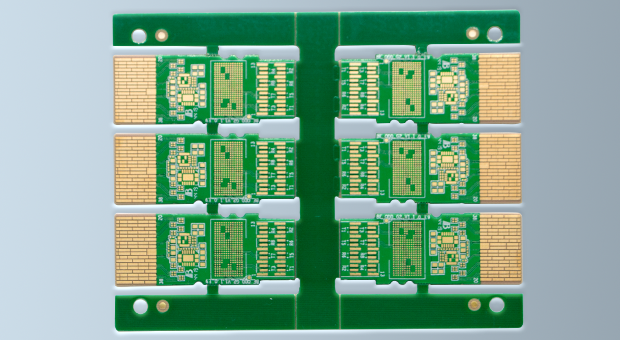

Full Category PCB Manufacturing Services

Unice Circuit: one PCB manufacturer with 20 years of expertise

Since 2005

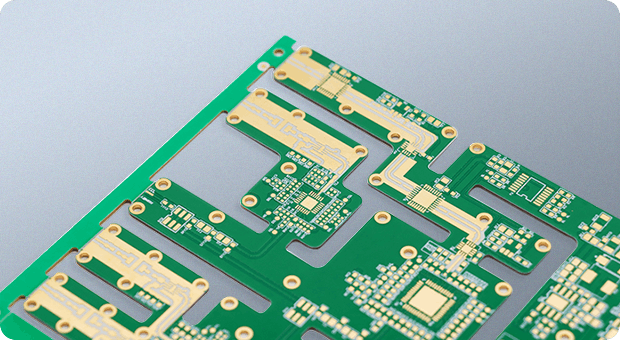

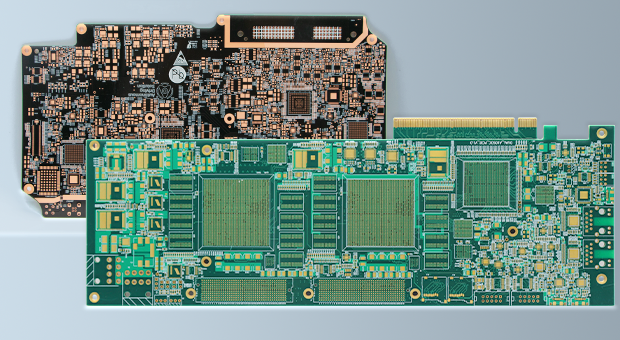

✅ 2 to 40-layer complex PCB

✅ 1 to 8-stage HDI PCB

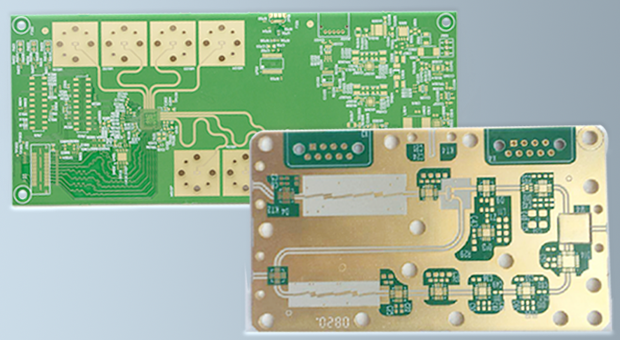

✅ 2 to 26-layer Rigid-flexible PCB

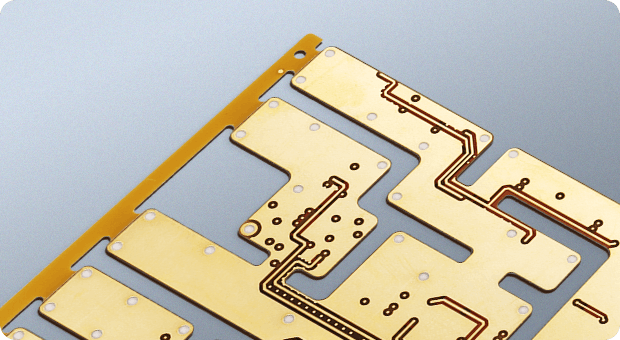

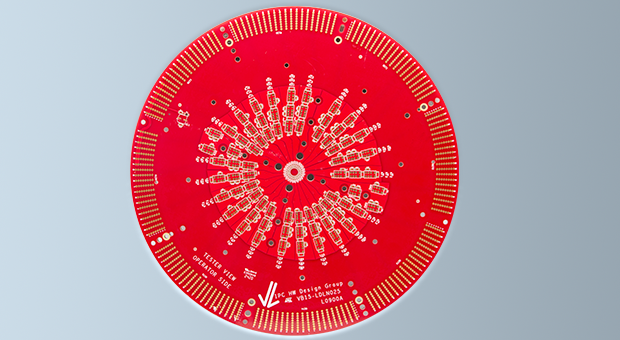

✅ Special PCB:Optical Module,Buried Capacitance,

Buried Resistance,IC Test,etc.