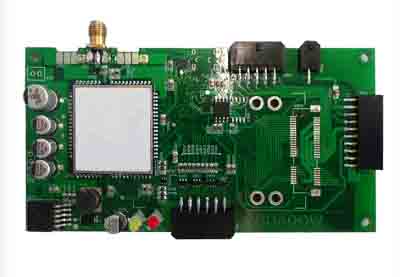

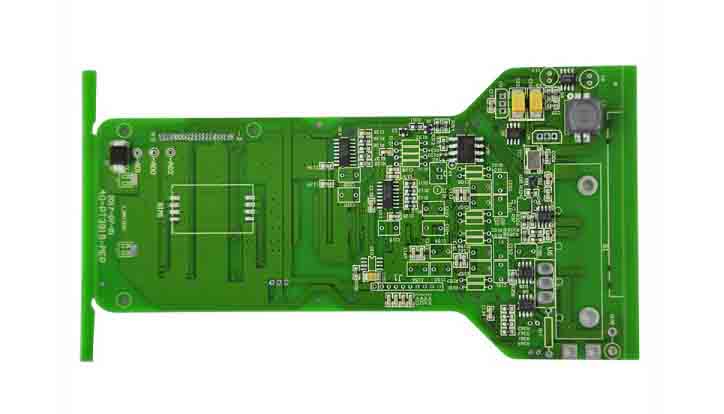

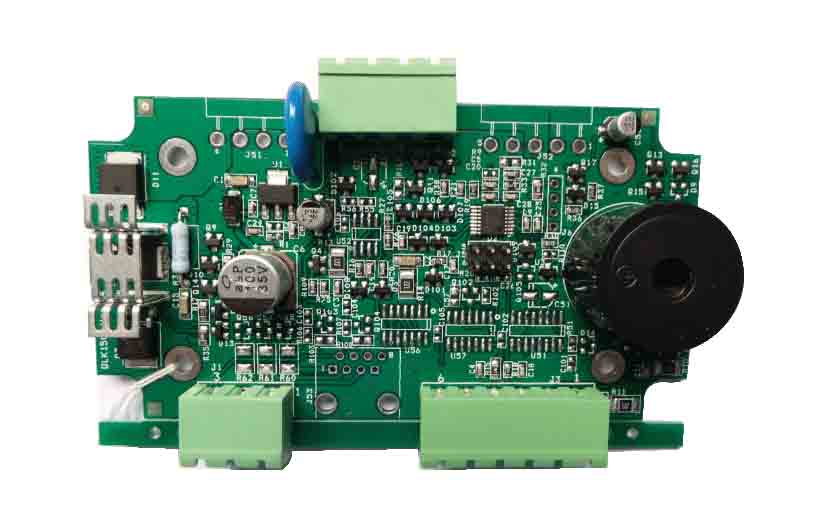

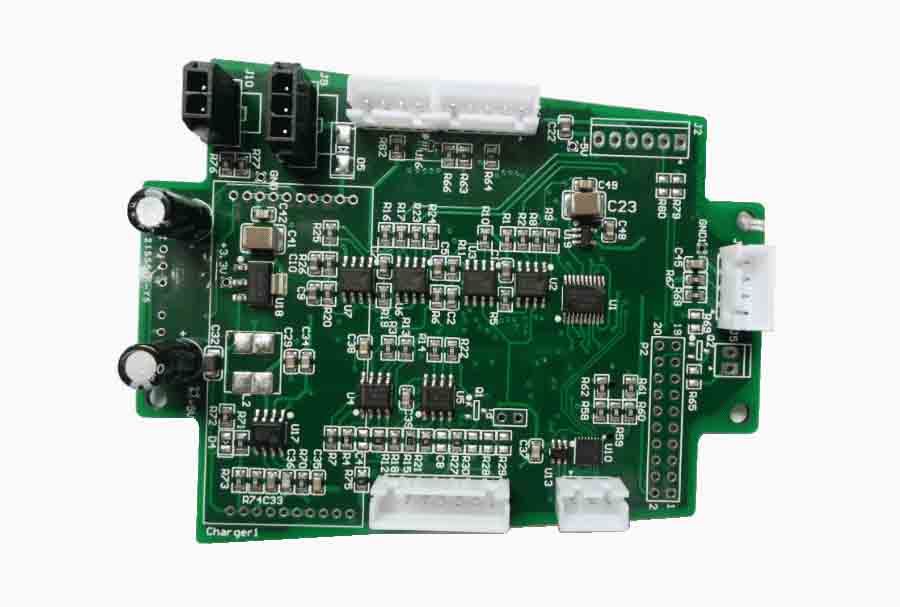

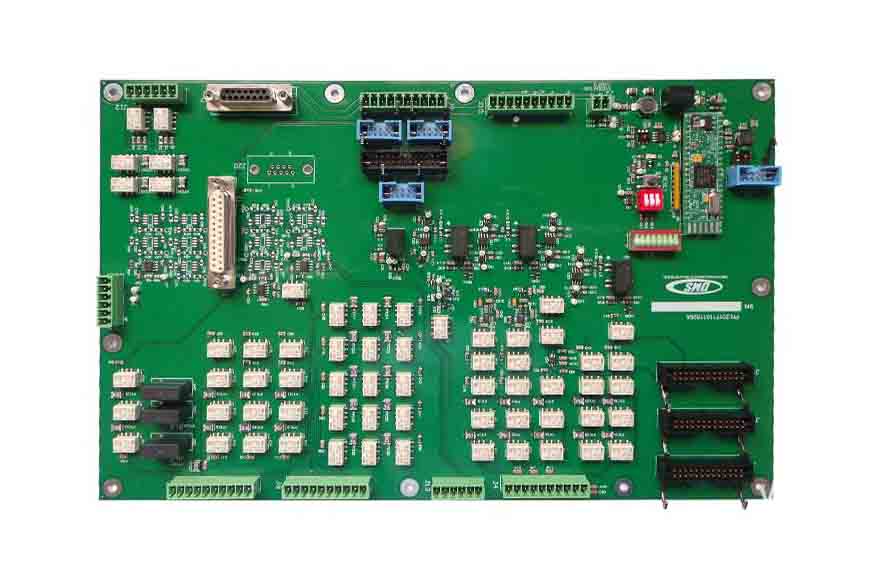

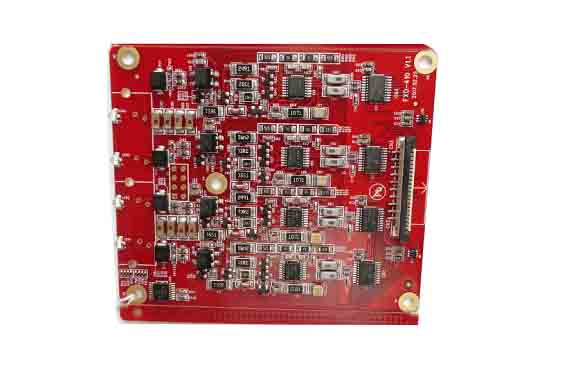

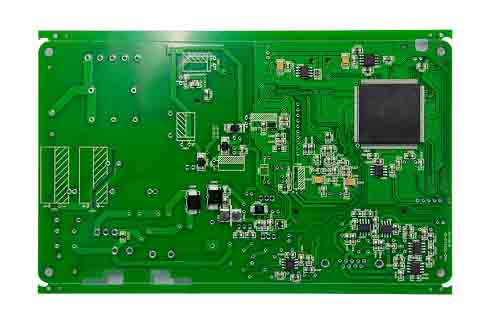

Turn-key PCB Assembly Services

Unice Circuit: PCB &PCBA manufacturer with 20 years of expertise

Since 2005

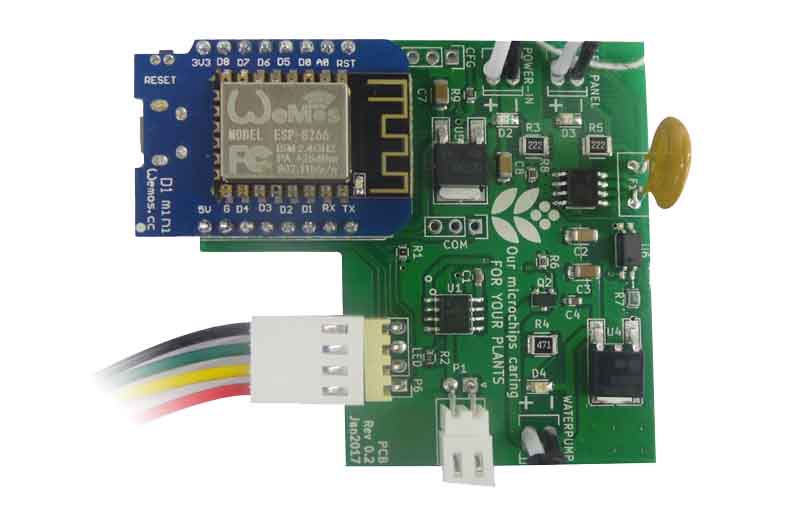

Dedicated to enabling a seamless journey from concept to market ,

accelerating your product's time-to-success.